Dublin, April 2025

At Carbon Collect, we believe that scaling Direct Air Capture (DAC) requires more than just ambitious plans—it demands systems designed for real-world scalability. Our MechanicalTree™ system exemplifies this philosophy, moving away from monolithic, centralized plants in favor of modular, passive units that grow through replication. This approach not only reduces costs and energy use, but also makes DAC deployment adaptable and scalable at gigaton capacity, transforming how we think about large-scale carbon removal.

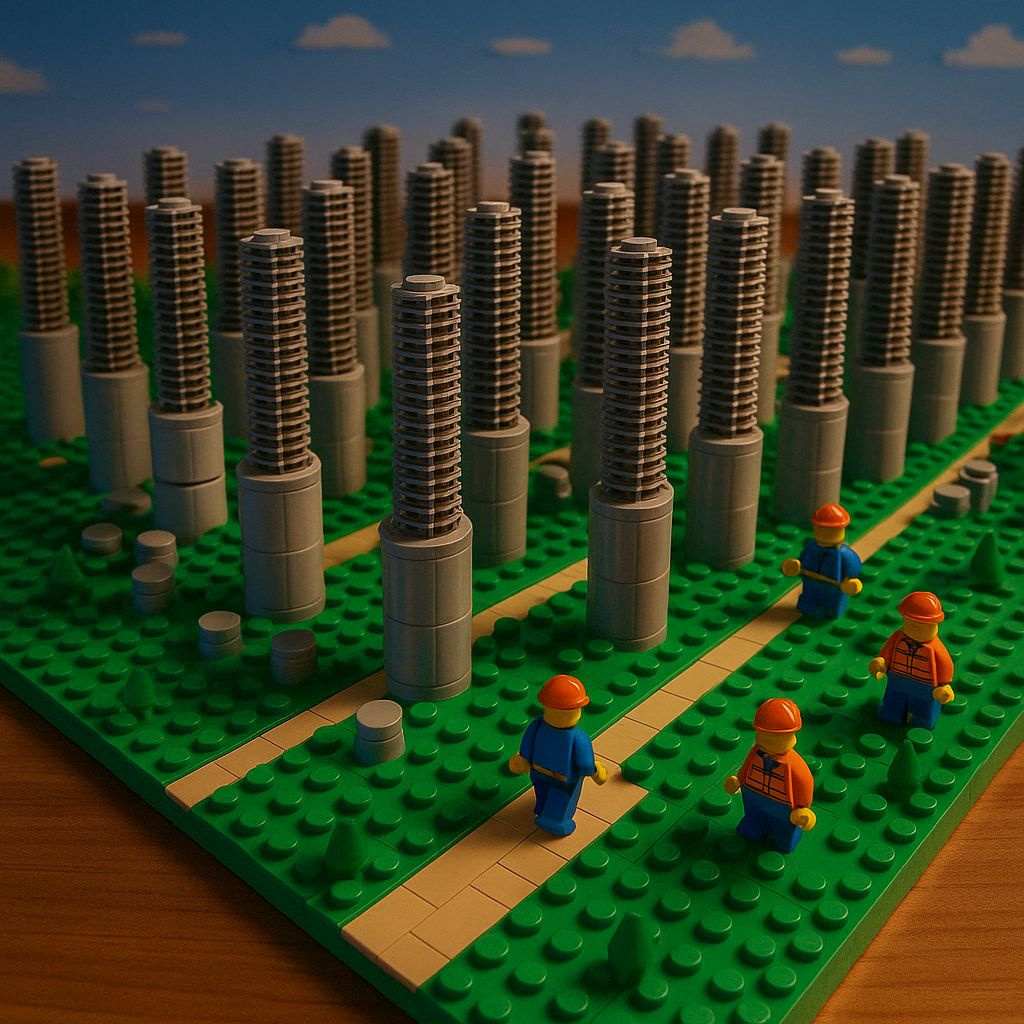

At Carbon Collect our journey with the MechanicalTree™ Passive direct air capture system reflects a consistent philosophy: DAC must be scalable by design, not just scalable in theory. While many DAC deployments focus on single, monolithic plants that aim to capture large volumes of CO2 per site, our approach is radically different. Our approach is building networks of passive, modular units, carbon farms, where capacity grows through replication, not redesign.

Each MechanicalTree™ CO2 capture module is optimized for mass production using low-cost, non-metallic materials and advanced sorbents. Our next generation system pushes energy recovery beyond 60%, reducing cost of capture. With embedded intelligence and deep reinforcement learning, our system will adapt dynamically to local conditions, grid signals, and utilization patterns.

Here’s the contrast: Others scale through massive upfront capex and centralized infrastructure. Carbon Collect’s MechanicalTree is designed to scale like solar and storage: modular, distributed, and rapidly deployable with standardized site preparation.

Our carbon farms can be co-located with data centers, concrete curing operations, greenhouses, or energy infrastructure, where CO₂ utilization has value. They can also be deployed at scale near geological storage sites for capture and permanent sequestration, enabling durable climate impact. We will deliver scalable carbon removal where it can be used or stored. We believe this is how DAC reaches the gigaton scale: not by betting on one megaproject, but by enabling thousands of smart, adaptable systems that grow where the world needs them most.

And for U.S. deployments, there’s more good news: our MechanicalTree™ system will be made in America. And because we don’t rely on energy-intensive fans, we avoid the hefty 145% tariffs now applied to the thousands of imported DAC fans used by other systems. It’s another way we’re making scalable carbon removal simpler, smarter, and more cost-effective.